Like Oil on Troubled Waters: The Future of Water Treatment

photo by Jacob Shorbphoto by Rob KerrLike Oil on Troubled Waters: The Future of Water Treatment

February 3, 2025 | by Bahman AbbasiIn a tightly packed exhibitors hall at the 2024 ARPA-E Energy Innovation Summit in Dallas, we could be found standing proudly next to the only 10-foot container in sight, unveiling a technology that could revolutionize how we manage water in North America’s most drought-prone regions.

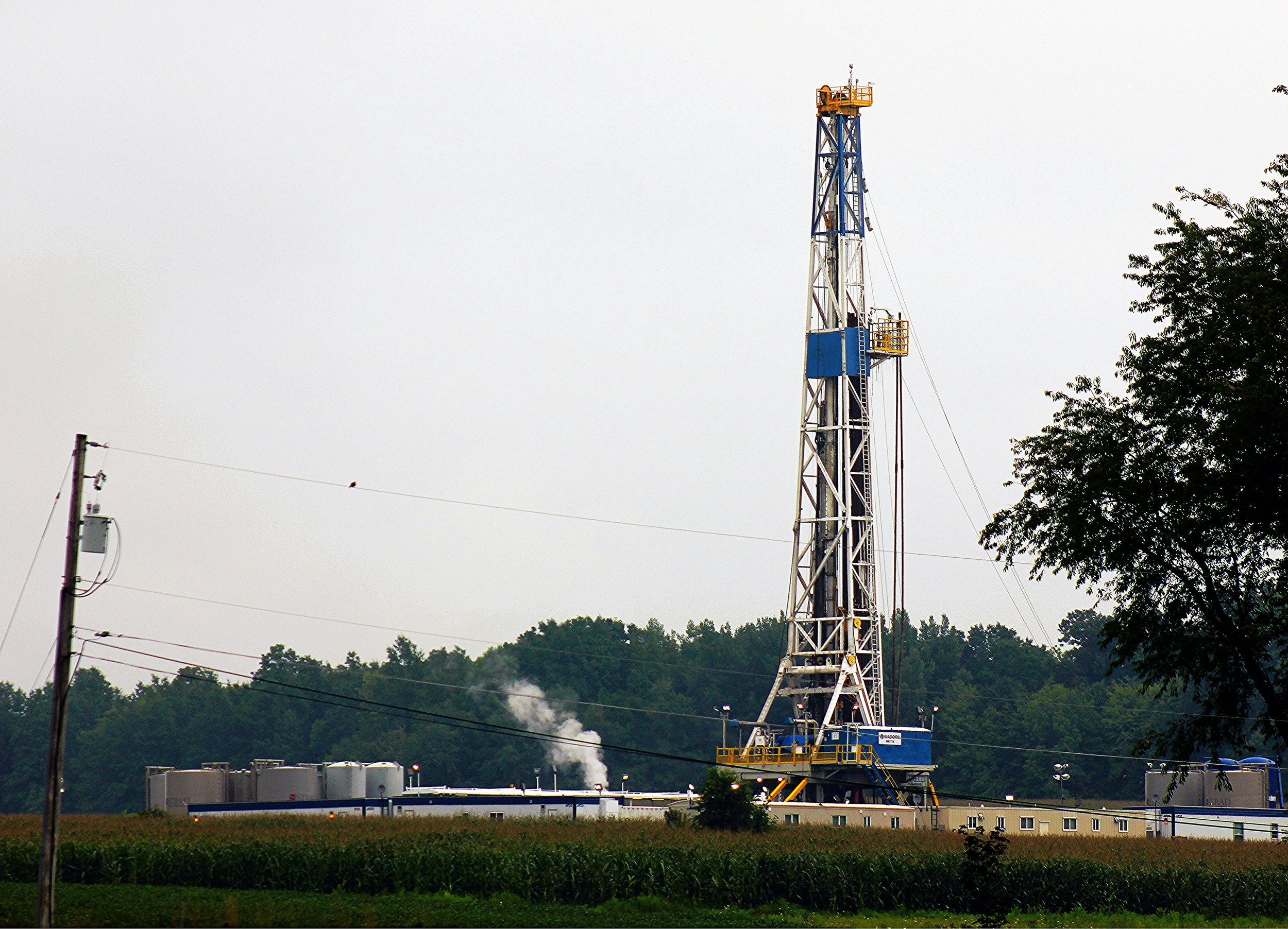

Oil & gas extraction is water-intensive, with ratios reaching up to 10 barrels of water for every barrel of oil produced, especially in aging wells. Texas is home to some of the most intensive drilling for this valuable fuel with an output of more than 2 billion barrels per year. In the desert expanse of western Texas, the Permian Basin consistently produces 50% of the total oil in the US, with up to 6.4 million barrels of crude oil produced each day. This part of Texas is not only dry on the surface, its groundwater is being depleted at record levels. This is the geological conundrum oil & gas producers face–where there is oil, water is scarce.

Currently, freshwater is pumped from the ground, used to displace crude oil to the surface via waterflooding, pumped out, trucked to another site where it is separated from hydrocarbons and deep well injected, posing threats to groundwater quality. This means communities in Midland County, TX for example, are faced with depleted freshwater, a threatened water supply, and heavy trucks on the road. According to a 2019 Texas Monthly article: “Driving on the highways alongside gigantic tankers and equipment haulers can feel like a suicide mission. Even some of those who are fiercely pro-oil have grown worried about the strain on the region’s limited natural resources—especially water—and the environmental toll of the proliferation of sand mining, the flares burning methane and benzene, and all the trash that litters the region.”

In comes midstream water production, a growing sector that has piqued the interest of sizable private investments to the tune of $16 billion in the oilfield water business alone. espiku’s produced water (PW) treatment technology hits many targets for investors and operators alike: distributed deployment and robust operation with complete fouling prevention, producing irrigation-quality water with 80% recovery, essentially eliminating the need to buy freshwater or pay for disposal, transport, or for the removal of associated gas.

Conventional treatment faces limitations due to the multitude of contaminants present in PW, including salts, oils, volatiles, organics, and acids. And thermally-driven technologies have been unsuccessful due to their energy requirements or cost of special materials rated for extreme heat. espiku upends how we approach treatment–we extract the water from the feedstock, leaving oils and salts behind, and even leveraging volatiles to fuel the unit’s heaters–and we can use any energy on site, including that associated gas.

Each unit produces hundreds of barrels of fresh, irrigation-quality water per day. Stack those and distribute the water as needed, and we have a win-win for the oil & gas industry and communities alike–no more trucking, no more deep-well injection, no more headaches.

A site-ready pilot container is being completed at our shop in Bend, OR as we speak. This year, we’ll test it on site and invite stakeholders to witness our unit in action. Then we’ll iterate, manufacture, and test in areas where water demands are even higher. And with Halliburton at our side, we gain access to communities that face increased pressures on roads and resources like Midland, TX. If we can make an impact here, we can make it anywhere.